Ultimate Guide to Steel Roof Ridge Cap Installation

Ultimate Guide to Steel Roof Ridge Cap Installation

Need to install a steel roof ridge cap installation? This guide covers every step, from understanding its importance to the final touches. Learn how to protect your roof effectively with our straightforward installation tips.

Key Takeaways

- Steel roof ridge caps provide essential protection against water damage and wind uplift, ensuring the integrity of metal roofing systems.

- Proper installation requires specific tools and adequate preparation, including leaving a gap for alignment and using sealants for waterproofing.

- Regular inspections and maintenance of the ridge cap post-installation are crucial for extending its lifespan and preventing significant repairs.

Understanding Steel Roof Ridge Caps

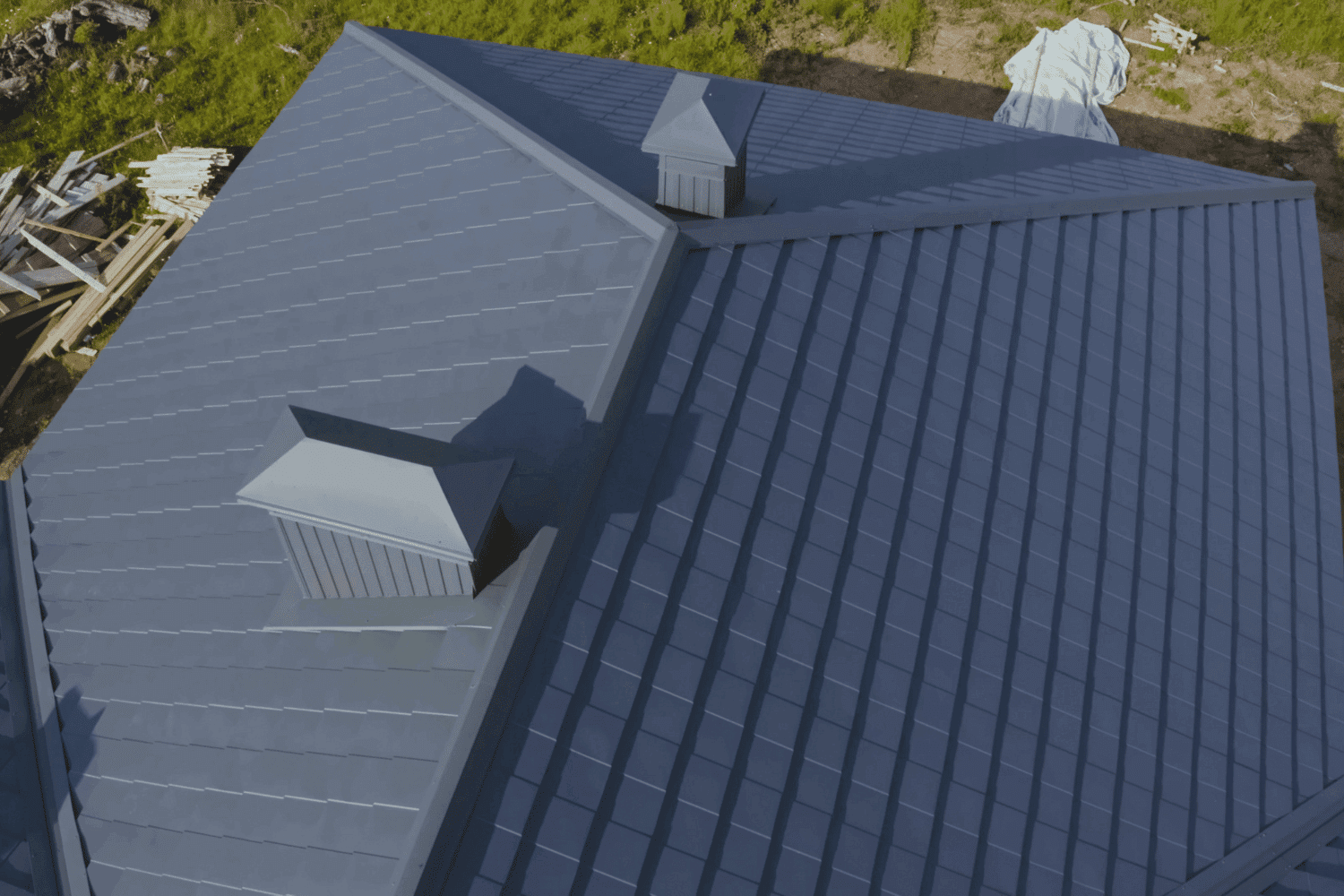

Steel roof ridge caps are trims installed along the peak of the roof, serving as the critical finishing touch that seals the joint between two roof slopes. They protect your roof from water damage and wind uplift, keeping your home dry and secure. Properly installed ridge caps prevent water from entering the roofing system, thereby safeguarding the interior of your home.

Common materials for metal roof ridge caps include aluminum and steel, chosen for their durability and resistance to the elements. These materials are designed to withstand the harshest weather conditions, providing long-lasting protection for your roof. The ridge cap’s role in a metal roofing system cannot be overstated, as it is instrumental in maintaining the roof’s overall integrity. Additionally, the metal roofing ridge cap plays a crucial part in this process.

Metal roof ridge caps come in two main varieties. These include closed ridge caps and vented ridge caps. Closed ridge caps are designed to completely seal the roof peak, providing maximum protection against water infiltration. On the other hand, vented ridge caps allow moisture to escape from the roof space while still offering essential weather protection. Understanding the differences between these types is crucial for selecting the right ridge cap for your metal roofing project.

Tools and Materials Needed for Installation

Embarking on a metal roofing project requires the right tools and materials to ensure a successful installation.

Essential tools for installing a metal roof ridge cap include:

- Cutting snips

- A carpenter’s pencil

- Cut-resistant roofing gloves

- A caulking gun

- Silicone sealant

These tools will help you measure, cut, and secure the ridge cap accurately, ensuring a professional finish.

Safety is paramount when working on a roof, so make sure to use safety equipment such as gloves and goggles to protect yourself. Additionally, metal-to-metal screws with sealing washers are necessary to secure the ridge cap properly.

It’s also crucial to read the manufacturer’s installation guide before starting the project to ensure you follow all guidelines and achieve a successful installation.

Preparing for Installation

Proper preparation is key to a successful installation process. Ridge caps are critical components that seal the joint between two roof slopes, preventing leaks and deterioration. They prevent water infiltration, safeguarding the interior from potential damage. A clean roof surface before installation is essential for strong adhesion of the ridge cap.

One important step is to leave a 2-inch gap between metal roofing panels at the peak to maintain alignment and allow for adjustments. This gap ensures that the ridge cap can be installed correctly and provides room for any necessary adjustments during the installation process. For non-vented ridge cap installations, foam closure strips seal gaps and prevent water infiltration.

For closed ridge caps, it’s necessary to prep the Z-trim underneath before installation. This preparation ensures that the ridge cap sits correctly and provides a secure seal. Taking these preparatory steps seriously will set the stage for a smooth and successful installation.

Cutting and Trimming the Ridge Cap

Cutting and trimming the ridge cap to fit your roof accurately is a crucial part of the installation process. Begin by measuring the ridge line’s length and width to ensure the ridge cap fits perfectly. Using a speed square, align it with the roof’s pitch before marking a cutting line on the ridge cap. This step ensures that your cuts are precise and the ridge cap aligns correctly with the roof’s angles.

To trim the ridge cap ends, create a one-inch mark, pry open the hems, and cut away one inch from each side. Then, fold the cut side down at a 90-degree angle to create a proper fit at the gable trim ends. This folding technique ensures that the ridge cap fits snugly and provides a clean finish at the roof edges. It’s also essential to smooth any rough edges or corners after cutting to ensure safety during installation and to prevent any potential damage to the roof.

Preparing the edge of the ridge cap properly is often considered the hardest part of the process, but it’s crucial for a successful installation. Accurate measurement and trimming ensure the ridge cap fits perfectly and provides maximum protection for your roof.

Installing the Ridge Cap

The installation process for a ridge cap begins with careful placement and alignment. Start by positioning the ridge cap along the ridge line, ensuring that there is room for expansion and contraction. Apply sealant tape along the ridge line to create a waterproof barrier where the ridge cap meets the panels. This step prevents water intrusion and ensures the longevity of the roof.

Techniques for attaching ridge caps depend on the type of closure, whether closed or vented. Overlap the ridge cap by a recommended 6 inches for proper sealing when the roof exceeds the typical length of the ridge cap.

The following subsections will detail the specific steps for securing closed ridge caps and installing vented ridge caps.

Securing Closed Ridge Caps

Securing closed ridge caps involves using butyl tape sealant to enhance the installation. This tape creates a waterproof seal, preventing any water from seeping through the ridge cap. Place the tape sealant along the edges of the ridge cap and press it firmly to ensure a tight seal.

Once the tape is in place, attach the ridge cap at regular intervals with screws, ensuring that it is securely fastened to the roof. This method provides a robust seal and prevents any movement of the ridge cap, maintaining the integrity of the roof structure.

These steps ensure closed ridge caps are installed correctly, providing maximum water and wind protection to install ridge cap correctly during ridge cap installation.

Installing Vented Ridge Caps

Installing vented ridge caps begins with proper positioning to ensure adequate airflow and moisture escape. Start by marking the installation location and making a cut 2 inches on either side of the centerline of the ridge. This cut allows for the vented ridge cap to fit correctly and perform its function of venting moisture from the roof space.

Position the vented ridge cap by aligning it with the marked installation location and securing it using an anchor clip system and tape seal. This system ensures that the vented ridge cap stays in place and provides a secure fit. After placing the profile vent, fasten the ridge cap to the clips with screws at regular intervals along its length.

Unlike closed ridge caps, ventilated ridge caps do not require sealant around the heads of screws. Follow the manufacturer’s specifications to ensure the vented ridge cap allows for adequate airflow and moisture escape. Adjust specialized closures as needed during the installation to accommodate the venting requirements.

Finishing Touches and Inspection

Once the ridge cap is installed, performing finishing touches and inspections is essential to ensure long-term effectiveness. Regular inspections can catch early signs of ridge cap damage, such as dents or rust, which could escalate into major repairs if left unchecked. After installation, ensure all screws are tightened to prevent potential leaks and maintain the roof’s integrity.

Inspecting and resealing the ridge cap regularly can significantly extend its lifespan. Performing these inspections and maintenance tasks ensures that your metal roof continues to protect your home effectively against weather and water damage.

Additional Tips for Successful Installation

For a successful installation process, consider choosing a ridge cap that complements the color and style of your metal roofing. This not only ensures a unified look but also enhances the overall aesthetic of your home.

Attention to detail in selecting materials can make a significant difference in the final appearance and performance of your metal roofing project.

Learn More About Metal Roofing Projects

To delve deeper into metal roofing projects, resources like the Metal Roofing Channel offer a comprehensive collection of videos covering various aspects of metal roofing. With over 500 videos available, you can find detailed guides and step-by-step instructions to help you tackle any metal roofing challenge.

Exploring various resources can help you gain a deeper understanding of metal roofing installations and achieve successful results in your projects.

Save Money on Your Metal Roofing Project

Saving money on your metal roofing project is possible with a few strategic steps. Check if manufacturers have surplus stock, as they may sell it at reduced prices. Buying from existing inventory can help you take advantage of lower prices before they are sold out.

Involving your installer early in the process can also identify cost-saving opportunities and ensure efficient use of materials. Ordering all necessary materials at once can streamline your project and potentially save you money.

Obtaining multiple quotes from different suppliers can help you find the most competitive pricing for your metal roofing project. Purchasing directly from manufacturers can often reduce costs since you cut out the middleman.

Summary

In summary, installing a steel roof ridge cap is a crucial step in ensuring the durability and effectiveness of your metal roof. By understanding the different types of ridge caps, preparing adequately, and following the correct installation steps, you can protect your home from water damage and extend the lifespan of your roofing system.

Armed with the right tools, materials, and knowledge, you can confidently take on this metal roofing project and achieve professional results. With regular inspections and maintenance, your metal roof will continue to safeguard your home for years to come.

Frequently Asked Questions

Why are ridge caps important for metal roofs?

Ridge caps are crucial for metal roofs as they seal the roof peak, effectively preventing water damage and reducing the risk of wind uplift. Ensuring proper installation of ridge caps is essential for the overall durability and functionality of the roof.

What tools do I need for ridge cap installation?

For ridge cap installation, you will need cutting snips, a carpenter’s pencil, cut-resistant gloves, a caulking gun, and silicone sealant. Ensuring you have these tools will help facilitate a smooth installation process.

How do I prepare my roof for ridge cap installation?

To prepare your roof for ridge cap installation, ensure the surface is clean and maintain a 2-inch gap between the roofing panels at the peak. This will facilitate proper ventilation and installation.

What is the difference between closed and vented ridge caps?

Closed ridge caps provide a watertight seal at the roof peak, whereas vented ridge caps facilitate moisture escape and enhance airflow, making them beneficial for roof ventilation.

How can I save money on my metal roofing project?

To save money on your metal roofing project, explore surplus stock, obtain multiple quotes, and consider buying directly from manufacturers. This approach can significantly reduce costs.

574-318-3326

574-318-3326